We design solutions

with the user and the environment in mind

Analysis and Planning

A new idea, customer insights, market research, new technology or inventions: these components often form the basis for a new product. We analyse all relevant input and carefully define the project’s boundary conditions, its starting points and the product specifications, or the specified product roadmap. Every development starts with a challenge, which at best has already generated a good idea. Therefore, we delve into this approach, check the feasibility, analyse the project (also for economic efficiency) and examine the technical and legal frameworks. Where necessary, we look for alternative solutions. Based on the results, we develop a concept from which the specifications for the design and development are drawn up.

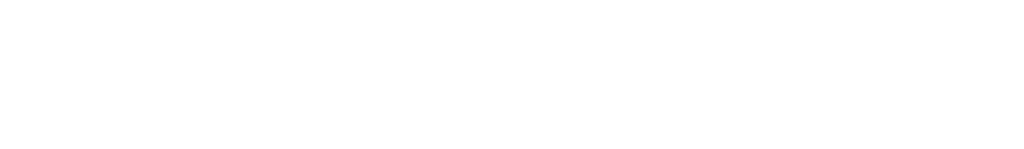

Development and Construction

During the planning phase, a vision becomes a concept. Our design department converts this concept into a virtual product. A 3D model is created and optimized by our experts in various dimensions, such as production conditions and flow properties. At the end of the process, the completed model forms the basis for the development of a prototype.

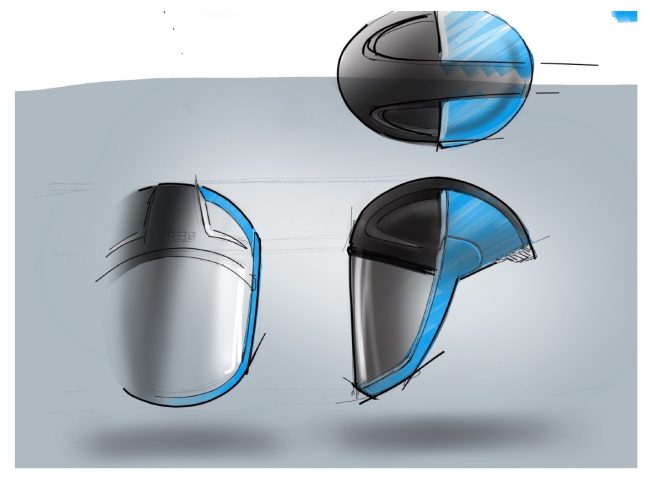

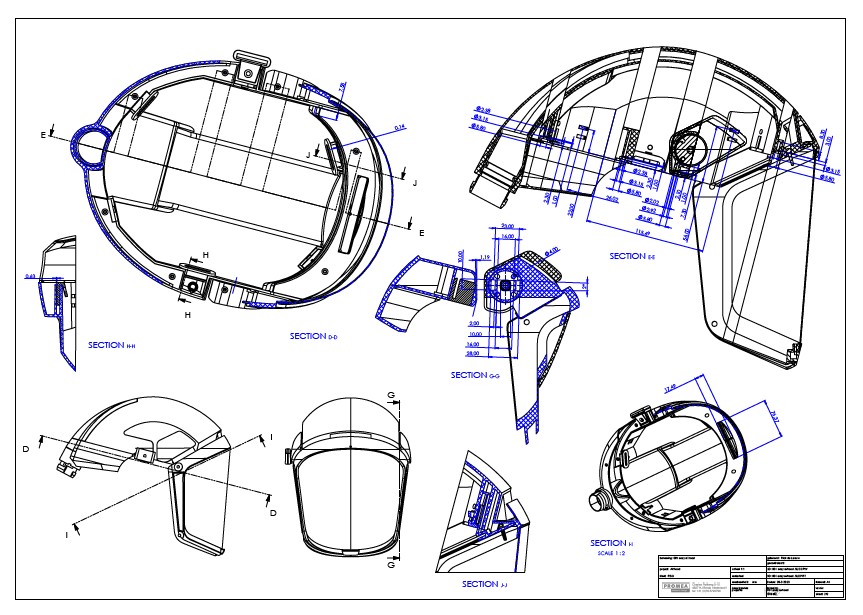

Engineering and Prototyping

The first stage of engineering is characterized by defining the raw structure and the main components of the concept. Based on a concept, our development department develops a 3D model and prototype. Early-stage investigation of actual proportions and crucial mechanical solutions to reduce the risk of delay or surprises to the absolute minimum. Using 3D printing, we create functional models from the model data. These models are tested and the results are used again in further product development until the completed prototype is available as a test model.

Testing and certification

Initial tests according to the applicable EN standards are carried out with prototypes close to production, as well as further tests depending on the requirement profile. In some cases the tests are carried out at our premises, but depending on the test procedure we also cooperate with external partners. Once all specifications are met and confirmed, the product can be certified.

Production

The development process is completed with a successful certification. The product is now ready for production. All processes of the necessary production chain are set up and supervised by us. From 0-series to series production, our products are manufactured exclusively in the Netherlands and EU countries – this guarantees short delivery times as well as a durable and more sustainable supply chain. Our choice of suppliers is based on the highest quality standards for production, the product and the environment.